Precision-fermented ingredients,

We engineered b-Rubber to meet growing material demand and increase rubber supply.

FROM BACTA'S PROCESS

- Sovereign production, security of supply

- Drop-in replacement for Natural Rubber

- Consistent quality, stable price

- Up to 190% emission reduction

FROM PETROCHEMICAL INDUSTRY

- Concentrated production, sovereignty issues

- Limited traceability

- Quality inconsistencies, price fluctuation

- Up to 14 tons of CO2 per ton of rubber

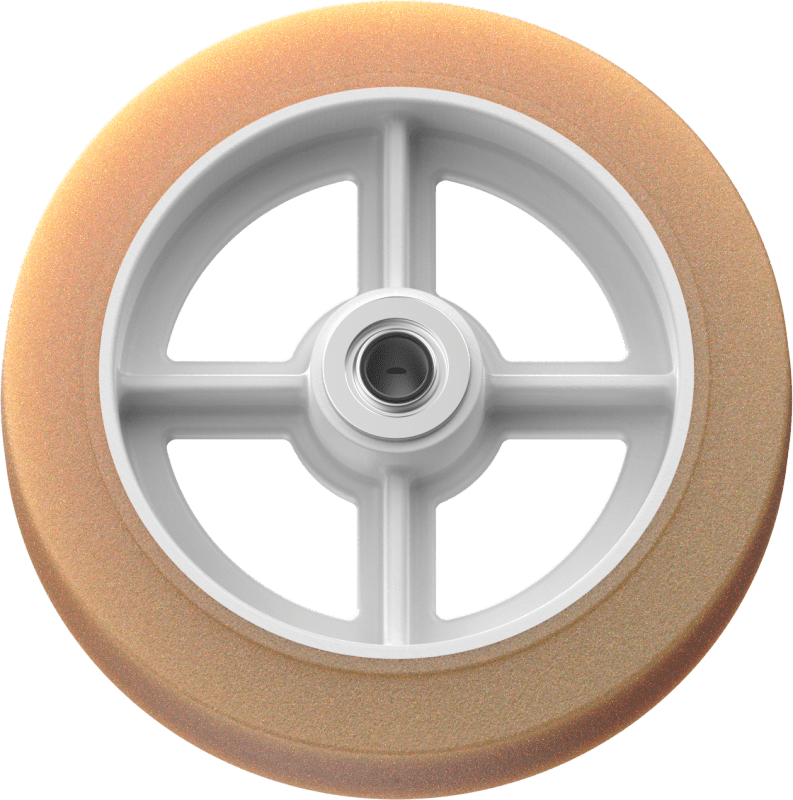

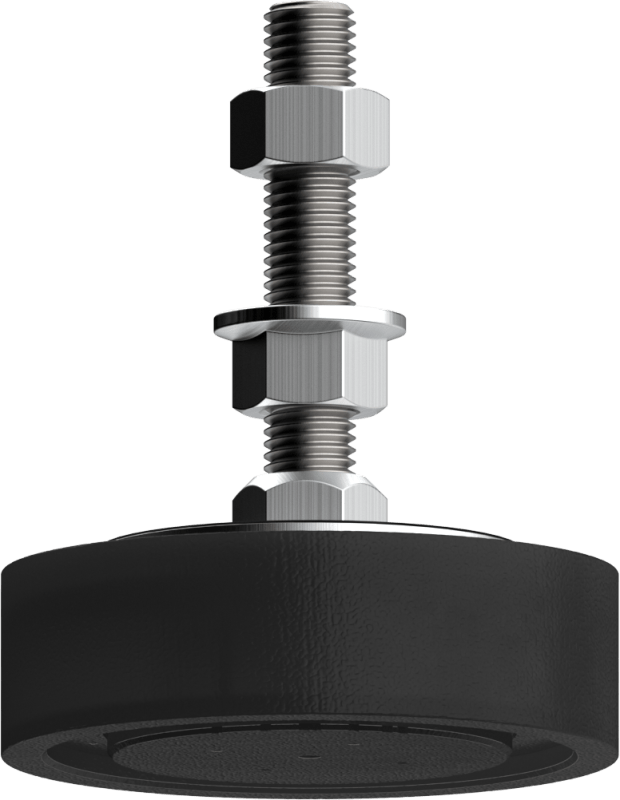

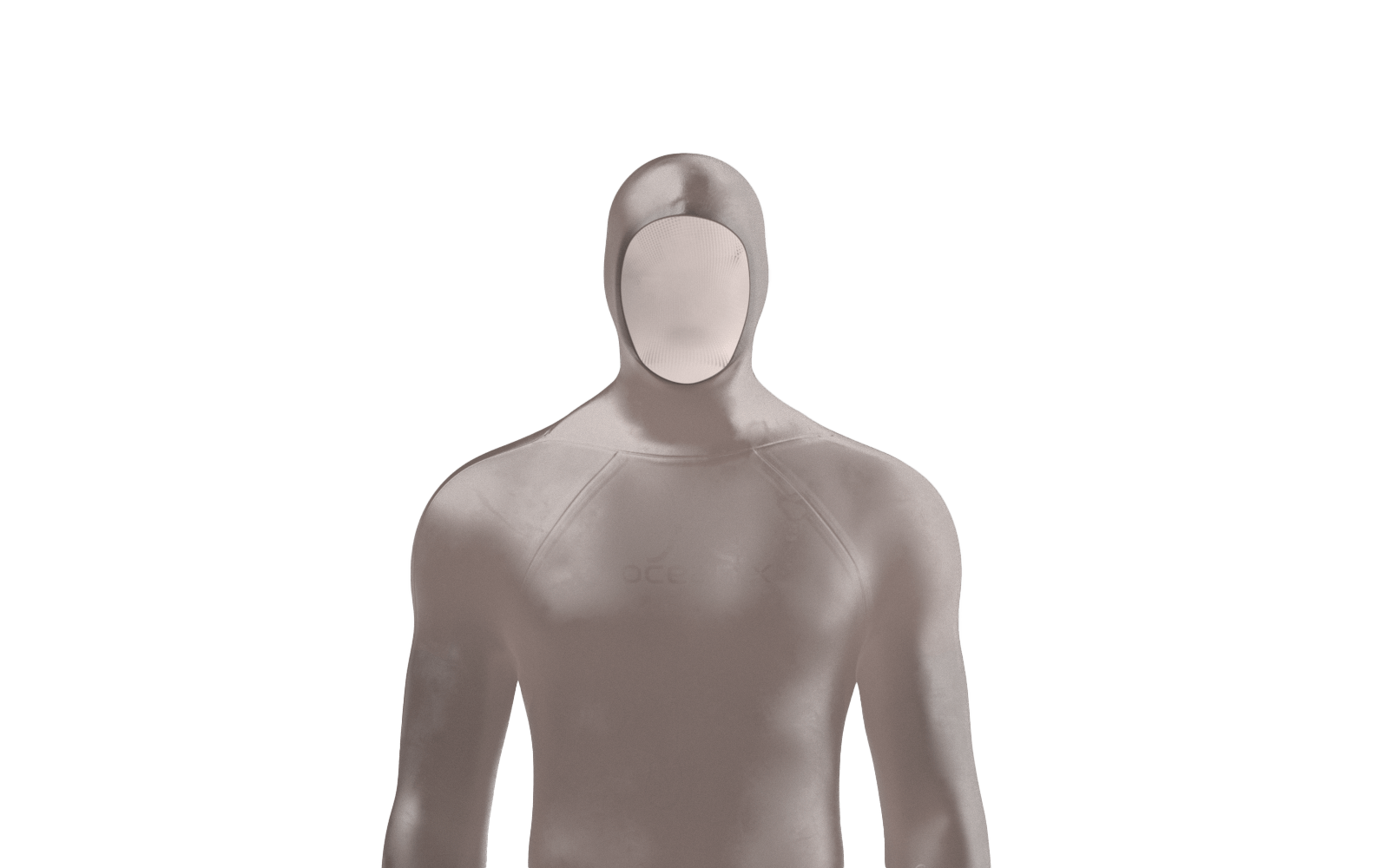

INDUSTRIAL APPLICATIONS

From ready-made clothing and luxury goods to industrial supplies, we provide biosynthetic materials as an alternative to rubber and oil-based composites.

THE SCIENCE BEHIND THE MOLECULE

Our platform rests

on 3 main pillars.

Tailor-made

Organelles

Metabolic hub in micro-organisms

Bioengineered

enzymes

AI + robotics discovery engine

Mixotrophy

Diversification of feedstock

OUR VISION

We unlock sustainable abundance of valuable molecules

Rubber is the first step in our platform. Our mission is to enable industries with biosynthetic materials and pave the way for sustainable abundance.

Latest news